Liquid diesel heater 9KW 12V Belief

This liquid diesel heater uses the gas or diesel as the fuel, heat the cooling liquid of the engine the forced-circulation water pump circulation in the cars waterway, prepare the engine and reduces the attrition achieves the purpose of eliminating the frost and warming the compartment.

Liquid diesel heater 9KW 12V Belief

Structure and working principles

Coolant circulation system

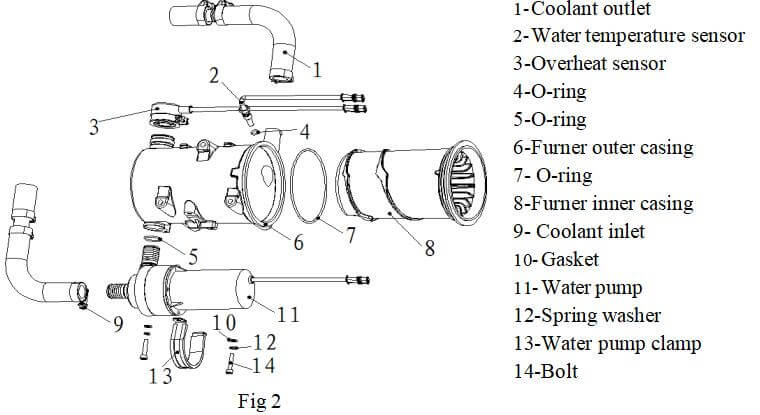

The cooling liquid of engine flows through water inlet pipe 9, water pump 11, the furnace cavity between the furnace inner casing 8 and outer casing 6, and water outlet pipe 1, forming a complete loop for the cooling liquid circulation system. The circulation is forced by water pump 11. In this way, the cooling liquid of the engine can be heated circularly in the furnace and the temperature of the engine, water tank, heat exchanger, and compartment can rise gradually.

The cooling liquid of engine flows through water inlet pipe 9, water pump 11, the furnace cavity between the furnace inner casing 8 and outer casing 6, and water outlet pipe 1, forming a complete loop for the cooling liquid circulation system. The circulation is forced by water pump 11. In this way, the cooling liquid of the engine can be heated circularly in the furnace and the temperature of the engine, water tank, heat exchanger, and compartment can rise gradually.

Overheat sensor 3 is used to measure the temperature of the furnace inner casing. The heater will be shut down automatically in case of overheating due to inadequate water in the furnace cavity or other problems.

Water temperature sensor 2 is used to measure the temperature of the coolant and determine whether the warm blower of the heat-exchanger in the car needs to be started and also determine the working conditions of the heater.

Product Description

| Heating Medium | Coolant | |||

| Thermal power | Max | 9.1KW | ||

| Regulating range | 2.0~7.6kW | 1.8~7.6kW | ||

| Fuel | Gasoline | Diesel | ||

| Fuel consumption | Max | 1.1 l/h | ||

| Regulating range | 0.25~1.0 l/h | 0.19~0.9 l/h | ||

| Power supply

(Common battery for the engine) |

DC12V | DC12/24V | ||

| Power consumption | Max | 90W | ||

| Regulating range | 37~83W | |||

| Working pressure | 2.0bar | |||

| temperature range | Control unit | Operation | -40~75℃ | |

| Storage | -40~85℃ | |||

| Fuel pump | Operation | -40~20℃ | ||

| Storage | -40~85℃ | |||

| Water pump circulation(0.15bar) | 1650 l/h | |||

| Net Weight (Only heater) | 4.8kg | |||

| Mobile phone control(Optional) | No limitation | |||

| Remote control(Optional) | Without obstacles≤800m | |||

| The temperature of coolant when the warm blower is started | 45℃ | |||

Advantages:

- Quiet operation to protect your comfortable ride

- Excellent Performance of the independent type of continuous heater capacity

- The perfect and simple control device

- Compact shape for easy installation on any vehicle

- Diagnosis function significantly reduces maintain time

About us

Our factory was established in April 1998, located in Harbin, Heilongjiang province.

We have an independent R&D organization and has established long-term cooperative relationships with state key universities and colleges like Harbin Institute of Technology, Harbin Engineering University, etc.

Annual production is more than 150,000 sets.

We exported to Europe, the United States, Canada, Japan, and etc 60 countries. We have sole dealers in AU and UK and Denmark.

| No. | Name | Specifications | Amount |

| 1 | Parking heater | 5KW | 1 |

| 2 | Timer | 1 | |

| 3 | Fuel pump | YB-Ⅰ-12V(24V) | 1 |

| 4 | Muffler | XYQ-Ⅰ | 1 |

| 5 | Wiring harness | 1 | |

| 6 | Water pump | 12V (24V) | 1 |

| 7 | Heater bracket | 1 | |

| 8 | Rubber cushion | 4 | |

| 9 | Muffler bracket | 1 | |

| 10 | Air inlet pipe | Φ20.5/Φ24 L=900 | 1 |

| 11 | Exhaust pipe | Φ24/Φ29.5 L=1000 | 1 |

| 12 | Positive wire of power supply | 1 | |

| 13 | Fuse base | With cover | 1 |

| 14 | Fuse | QY169-5A | 1 |

| 15 | Fuse | 12V/20A(24V/15A) | 1 |

| 16 | Fuse | QY169-25A | 1 |

| 17 | Water pipe | Φ17/Φ27 L=2600 | 1 |

| 18 | Clip | 16-25 | 1 |

| 19 | Spring clip | Φ24×Φ27 | 10 |

| 20 | Oil pump clip | Φ32 | 1 |

| 21 | Oil pipe clip | 8-10 (9-11) | 12 |

| 22 | Exhaust pipe clip | Φ24-28 | 3 |

| 23 | Air inlet pipe fixing clip | Φ24 t=0.5 | 2 |

| 24 | Exhaust pipe fixing clip | Φ27 t=0.8 | 2 |

| 25 | Fuel pipe | GasolineΦ1.5×Φ4(DieselΦ2×Φ5) | 1 |

| 26 | Fuel pipe connector | Φ3.5/Φ9.5(Φ4.1/Φ10.5) | 6 |

| 27 | water pipe connector | Φ18 L=55 | 2 |

| 28 | Special water pipe connector | PPA +33 Φ20×Φ18 L=60 | 2 |

| 29 | Relay | 4141(only for 12V) | 1 |

| 30 | Filter | RYL-Ⅰ(only for diesel) | 1 |

| 31 | Bolt | M6×10 | 1 |

| 32 | Self drilling tapping screw | ST5.5×25 | 6 |

| 33 | Self drilling tapping screw | ST5.5×30 | 5 |

| 34 | Self tapping screw | ST3×20 | 1 |

| 35 | Self tapping screw | ST4×16 | 3 |

| 36 | Spring washer | Φ6 | 2 |

| 37 | Washer | Φ6/Φ12 | 2 |

| 38 | Nut | M6 | 1 |

| 39 | Fuel suction pipe | XYG-Ⅰ 3×400 | 1 |

| 40 | Plug | DJ7041A-2.8-21 | 1 |

| 41 | Nylon cable ties | 4×150 | 1 |

| 42 | Nylon cable ties | 4×200 | 1 |

| 43 | Instruction manual | 1 | |

| 44 | Reducing T | Φ6-Φ10/Φ10 | 1 |

| 45 | Oil pipe clip | 12-14 | 2 |

| 46 | Non-return valve | D18 | 1 |

| 47 | Transition elbow | 2 | |

| 48 | Fixing gear | 2 | |

| 49 | O-ring | 14.8×2.62 | 2 |

| 50 | Bolt | M6×95 | 4 |